Choosing the right flange size for short tube headers is crucial for optimizing exhaust system performance. It involves accurately measuring the header diameter, considering gas flow requirements, and ensuring compatibility with nearby components like mufflers or intake systems. By selecting the appropriate flange, you ensure seamless fitment, enhance engine power, and maximize the benefits of short tube headers in your vehicle's architecture.

Choosing the right flange size is crucial for a seamless fitment of short tube headers in automotive applications. This guide explores the essential aspects of flange sizing, focusing on their role in enhancing engine performance and cooling systems. We’ll break down key factors to consider, from material compatibility to pressure ratings, ensuring accurate selection for optimal results with short tube headers.

- Understanding Flange Sizes and Their Role in Short Tube Headers

- Key Factors to Consider When Choosing Flange Size

- Step-by-Step Guide to Ensure Accurate Flange Size Selection for Short Tube Headers

Understanding Flange Sizes and Their Role in Short Tube Headers

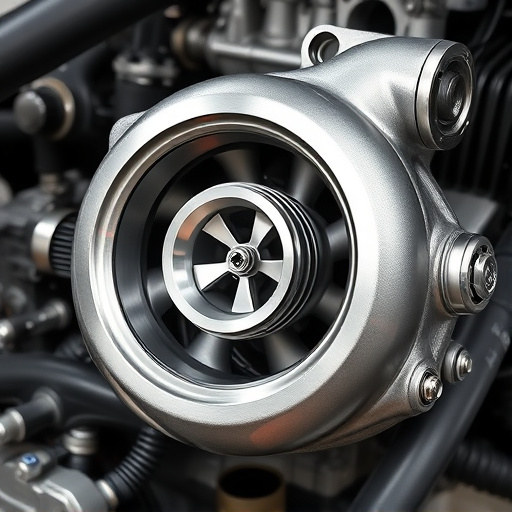

Choosing the right flange size is paramount when fitting short tube headers, as these components play a crucial role in the overall performance and efficiency of your exhaust system. Flanges are essentially the connection points where tubes meet other parts like headers, manifolds, or exhaust mufflers. The primary function of a flange is to provide a sealed joint, ensuring gases flow smoothly within the short tube headers and minimizing leaks.

Different flange sizes cater to various applications, including those used in custom exhaust systems, cold air intakes, or as part of performance upgrades. When selecting a flange size for short tube headers, consider factors like the overall diameter of the tubes, the specific requirements of your exhaust system (e.g., for improved gas flow), and compatibility with other components like exhaust headers and mufflers. Understanding these aspects ensures optimal fitment, enhances engine performance, and contributes to a more efficient exhaust system.

Key Factors to Consider When Choosing Flange Size

When selecting a flange size for short tube headers, several key factors come into play to ensure a perfect fit and optimal performance. The primary consideration is the overall diameter of your short tube header assembly, as this will dictate the corresponding flange size required. It’s crucial to measure the header carefully to avoid any missteps during installation.

Additionally, the type of brake components and high-performance parts you intend to integrate with the short tube headers should influence your decision. Different setups may necessitate specific flange sizes to accommodate various exhaust configurations, such as adding muffler tips or other aftermarket enhancements. This tailored approach ensures a secure fitment, allowing for efficient gas flow and enhancing overall engine performance.

Step-by-Step Guide to Ensure Accurate Flange Size Selection for Short Tube Headers

Selecting the right flange size for short tube headers is a meticulous process that requires a step-by-step approach to ensure optimal fitment and performance. Begin by accurately measuring the diameter of your existing header or the space allocated for installation. This foundational step sets the stage for precise flange selection, aligning with your vehicle’s architecture. Next, consider the overall configuration of your short tube headers, factoring in factors like bend radius, muffler tips, and air intake systems to ensure compatibility.

Refer to the specifications provided by the manufacturer of your high-performance parts, as they often offer detailed guidelines for flange size recommendations. This guidance will help you avoid issues during installation, ensuring a seamless fit that enhances the overall efficiency of your vehicle’s engine, especially when modifications are made with custom air intake systems in mind.

When selecting flange size for your short tube header installation, consider the vehicle’s make and model, the desired performance outcome, and the compatibility of flanges with the available gaskets and bolts. By following a systematic approach outlined in this article, you can ensure the optimal fitment of short tube headers, enhancing engine performance while maintaining safety and reliability.