Short tube headers, popular among automotive enthusiasts, enhance performance through improved gas dynamics and efficient exhaust evacuation. Ideal for high-performance vehicles with coilover kits and advanced brake rotors, they significantly boost engine power. Key components include flanges, tubes, collectors, and gaskets, with proper flange size selection crucial for optimal performance and installation. Selection involves balancing vehicle-specific requirements, compact design, material thickness, and air intake compatibility. Following industry standards and manufacturer guidelines ensures enhanced performance, reliability, and easy installation.

Choosing the right flange size for your short tube header fitment is crucial for optimal performance. This guide dives into the essentials of understanding short tube headers and their components, outlining key factors like bore size, material, and intended application. By following a step-by-step approach, you’ll learn to balance compatibility with engine requirements, ensuring efficient gas flow and long-lasting reliability. Discover the ins and outs of selecting the perfect flange size for your custom short tube header project.

- Understanding Short Tube Headers and Their Components

- Factors to Consider When Choosing Flange Size

- Step-by-Step Guide to Determining the Optimal Flange Size

Understanding Short Tube Headers and Their Components

Short tube headers are a popular choice among automotive enthusiasts looking to enhance their vehicle’s performance. These headers are designed with shorter tubes and optimized flow paths, allowing for improved gas dynamics and efficient exhaust gas evacuation. This configuration is particularly beneficial for high-performance vehicles equipped with coilover kits and advanced brake rotors, as it can significantly boost engine power and overall driving experience.

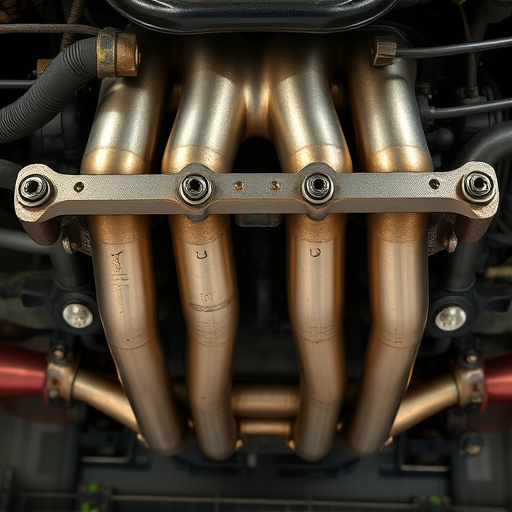

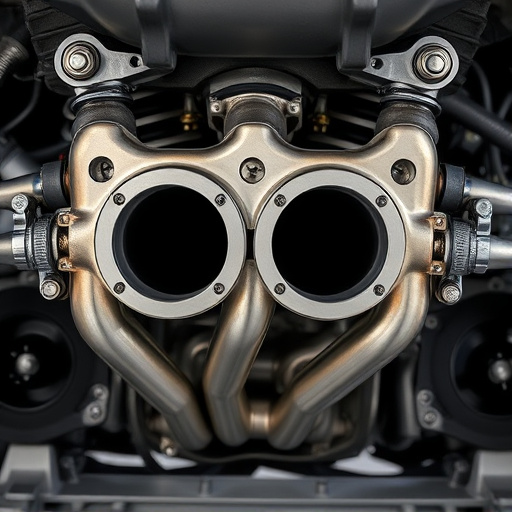

The components of a short tube header include the flanges, tubes, collectors, and various gaskets. Flanges play a crucial role in connecting the header to the engine’s cylinder heads, ensuring a secure fitment. The size of these flanges must be carefully considered to match the specifications of the engine and the overall header design. By selecting the right flange size, you can ensure optimal performance and prevent any potential issues during installation, such as misalignment or inadequate sealing, which could compromise the effectiveness of high-performance parts.

Factors to Consider When Choosing Flange Size

When selecting a flange size for short tube headers, several key factors come into play, ensuring a precise and efficient fitment process. Firstly, consider the specific application and vehicle requirements. Different cars have varying exhaust systems, including mufflers and headers, so understanding your vehicle’s setup is essential. Short tube headers often require custom fitting due to their compact design, which means the flange size must align with the engine’s configuration.

Additionally, the material and thickness of the header play a role. Thicker materials handle higher heat and pressure better, influencing the choice of flange size and strength. In terms of integration, ensuring compatibility with existing air intake systems is crucial to maintain optimal airflow. Balancing these considerations allows for a seamless installation, enhancing both performance and reliability in custom automotive engineering projects, particularly with short tube headers and their associated exhaust mufflers and systems.

Step-by-Step Guide to Determining the Optimal Flange Size

To determine the optimal flange size for short tube headers, follow a systematic approach that aligns with your vehicle’s specific needs and the performance goals you aim to achieve. Start by measuring the diameter of the tubes that will be connected to the header. This is a crucial first step as it sets the foundation for all subsequent calculations. Next, consider the type of cold air intake (CAI) or air filter kits you plan to install, as these components influence the overall clearance and fitment requirements. Additionally, assess your vehicle’s suspension kits, as they can impact the header’s mounting points and overall design.

With this information in hand, consult industry standards and manufacturer guidelines to identify flange sizes that accommodate your chosen components while ensuring proper sealing and minimal clearance issues. A common practice is to select a flange size slightly larger than the tube diameter, allowing for flexibility during installation and accommodating any potential thermal expansion. This step-by-step guide ensures a seamless fitment process for short tube headers, enhancing engine performance without compromising on efficiency or reliability.

When fitting short tube headers, selecting the right flange size is key. By considering factors like engine type, cooling requirements, and pipe diameter, you can ensure optimal performance. Using a step-by-step guide ensures precision in determining the best flange size for your specific short tube header application, ultimately enhancing overall system efficiency.