Short tube headers for front-wheel-drive vehicles offer enhanced performance and aesthetics through improved air flow, optimized power delivery, and aggressive styling. Crafted with advanced engineering, CNC machining, and stainless steel, they endure high-performance conditions. Precise installation and regular maintenance are crucial for optimal efficiency and longevity, complementing upgrades like suspension kits and cat back exhaust systems.

Short tube headers are a game-changer for front-wheel-drive (FWD) applications, offering enhanced performance and efficiency. This article delves into the benefits of integrating these headers into FWD vehicles, exploring their design, manufacturing techniques, and installation best practices. By understanding the advantages and proper maintenance, you can ensure longevity and optimal output, making short tube headers a must-consider upgrade for your FWD setup.

- Understanding Short Tube Headers: Benefits for FWD Vehicles

- Design and Manufacturing Techniques for Optimal Performance

- Installation and Maintenance Tips: Ensuring Longevity and Efficiency

Understanding Short Tube Headers: Benefits for FWD Vehicles

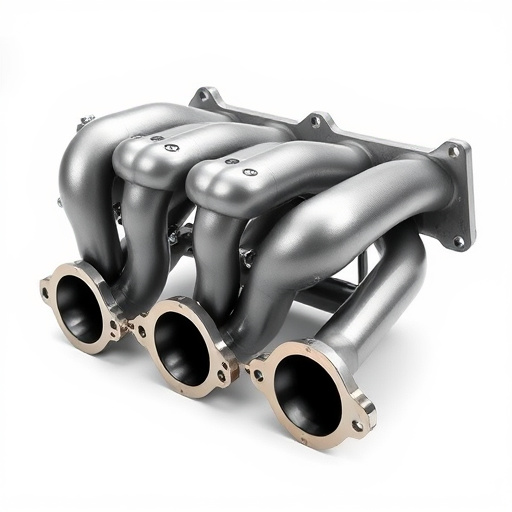

Short tube headers are a popular upgrade for front-wheel-drive (FWD) vehicles, offering numerous advantages that can significantly enhance both performance and aesthetics. In contrast to traditional long tube headers, short tubes are designed with compactness in mind, allowing for better air flow and improved engine efficiency. This is particularly beneficial for FWD cars, as it helps to optimize power delivery to the wheels while reducing backpressure in the exhaust system.

One of the key benefits of short tube headers for FWD applications is their ability to complement high performance parts such as suspension kits. By promoting better combustion and efficient gas flow, these headers can unlock hidden horsepower, resulting in improved acceleration and overall vehicle performance. Additionally, short tube headers often come with a sleek design that can showcase the vehicle’s aggressive style, making them a popular choice among car enthusiasts looking to enhance both functionality and visual appeal with cat back exhaust systems.

Design and Manufacturing Techniques for Optimal Performance

The design and manufacturing process of short tube headers for front-wheel-drive applications is a precise art, tailored to deliver optimal performance. These headers are crafted with advanced engineering techniques, ensuring efficient gas flow and maximizing power extraction. By employing cutting-edge computer-aided design (CAD) software, manufacturers can create intricate configurations that optimize the path of exhaust gases, reducing backpressure and enhancing engine breathing.

Manufacturing involves a meticulous process, starting with precision CNC machining to shape the short tube headers to exact specifications. The use of high-quality materials, such as stainless steel known for its corrosion resistance and strength, is paramount. Additionally, advanced welding techniques ensure structural integrity, allowing these headers to withstand the rigorous demands of high-performance vehicles equipped with coilover kits and powerful performance brakes. Incorporating features like strategic weld patterns and enhanced joint reinforcement further contributes to their durability, ensuring long-lasting reliability in demanding driving conditions.

Installation and Maintenance Tips: Ensuring Longevity and Efficiency

The installation of short tube headers is a precise process that requires careful attention to detail. To ensure optimal performance and longevity, it’s crucial to follow manufacturer guidelines and engage professional installers who understand the intricacies of front-wheel-drive (FWD) applications. Proper alignment and sealing are paramount; any misalignment can lead to decreased efficiency and potential damage to surrounding components, especially in compact vehicle designs.

Regular maintenance plays a significant role in keeping short tube headers functioning at their best. This includes periodic inspections for leaks, tightening of connections, and checking the condition of gaskets. Upgrading to high-performance exhaust systems or performance brakes can further enhance efficiency, but it’s essential to balance these upgrades with proper maintenance to avoid complications and maximize the benefits of your short tube header investment.

Short tube headers are a game-changer for front-wheel-drive applications, offering significant performance improvements through enhanced cooling and gas flow. By understanding their benefits, adopting optimal design and manufacturing techniques, and practicing proper installation and maintenance, vehicle owners can fully leverage the advantages of these components. Incorporating short tube headers into FWD systems is a strategic move that promises both efficiency and longevity.