By 2025, short tube header design trends favor sleek minimalism with clean lines and precision shapes, often finished in matte black or stainless steel. Integrating performance upgrades like coilover kits and air filters prioritizes improved airflow while maintaining a low profile. Market advancements include lightweight materials like titanium and advanced manufacturing techniques like 3D printing, improving gas flow, engine responsiveness, fuel efficiency, and aesthetic appeal. Advanced materials and precise engineering enhance durability and power output, driven by growing demand for both performance and efficiency.

In 2025, the short tube header design landscape is set to evolve with innovative aesthetics, performance optimizations, and material breakthroughs. As automotive demands shift towards enhanced power and efficiency, modern short tube headers are reimagined with streamlined, yet robust designs. This article explores emerging trends in short tube headers, highlighting advancements that promise improved durability, increased flow, and unparalleled performance for the year ahead.

- Evolving Aesthetics: Modern Designs for Short Tube Headers

- Performance Optimization: Key Trends in 2025 Market

- Material Innovations: Enhancing Durability and Efficiency

Evolving Aesthetics: Modern Designs for Short Tube Headers

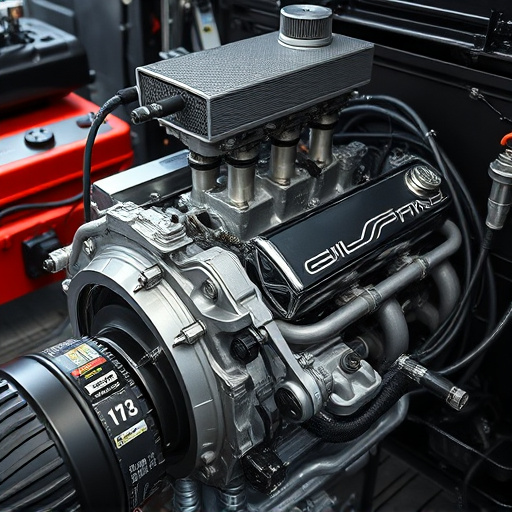

In 2025, the performance market is witnessing a significant shift in short tube header design aesthetics. Modern trends lean towards sleek, minimalist looks that blend seamlessly with contemporary vehicle styles. These headers are no longer solely functional components but have become integral parts of the car’s visual appeal. Clean lines, smooth curves, and precision-cut shapes define the new wave of designs, often accentuated by high-quality finishes like matte black, stainless steel, or even textured coatings. This evolution in aesthetics caters to the growing demand for vehicles that exude both power and style.

The integration of performance upgrades such as coilover kits and suspension kits has influenced header design, with manufacturers focusing on improving airflow while maintaining a low, aggressive profile. Additionally, high-performance air filters have become more prominent, allowing for enhanced engine breathing and contributing to the overall aesthetic appeal of these headers. These advancements not only boost engine performance but also ensure that short tube headers remain a key element in the customization landscape for auto enthusiasts.

Performance Optimization: Key Trends in 2025 Market

In the 2025 market, performance optimization for short tube headers is poised to reach new heights. The trend leans heavily on advanced engineering and material science innovations, enabling more efficient gas flow and improved engine responsiveness. Key developments include the adoption of lightweight materials like titanium and high-performance stainless steels, which significantly reduce weight without compromising durability. Additionally, computer-aided design (CAD) and computational fluid dynamics (CFD) simulations play a pivotal role in crafting headers that deliver unparalleled power outputs while enhancing fuel efficiency.

Another notable trend is the integration of advanced manufacturing techniques like 3D printing and laser welding. These technologies allow for intricate designs tailored to specific engine requirements, maximizing performance exhaust potential. The market also witnesses a growing preference for cat-back exhaust systems featuring sleek, stylish exhaust tips. These systems not only enhance the overall aesthetic appeal but also offer better sound quality without sacrificing performance. This combination of form and function promises to revolutionize the short tube headers segment in 2025.

Material Innovations: Enhancing Durability and Efficiency

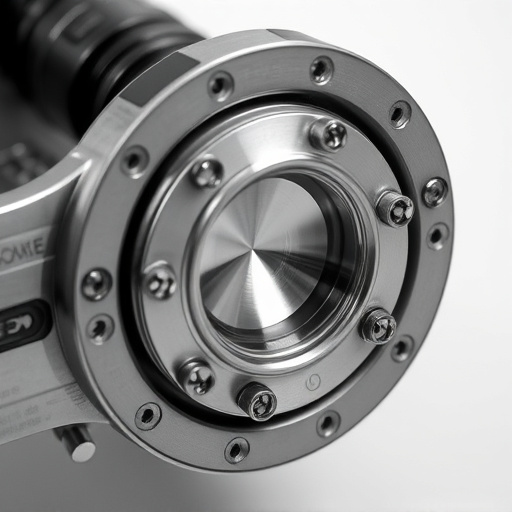

In the 2025 performance market, material innovations are revolutionizing short tube headers, enhancing both durability and efficiency. Advanced materials such as lightweight alloys and high-strength steels are being incorporated into header design to withstand extreme temperatures and pressure generated by high-performance parts like cold air intakes. These advancements not only ensure the longevity of short tube headers but also optimize their performance, contributing to overall engine efficiency.

Additionally, innovative manufacturing techniques enable precise engineering and tighter tolerances, resulting in improved flow dynamics within the header. This, in turn, enhances the gas exchange process, boosting the overall performance of the exhaust system, particularly when coupled with high-performance exhaust systems. As the demand for power and efficiency continues to grow, material innovations and meticulous design will remain paramount in shaping the future of short tube headers.

The future of short tube headers in 2025 promises a blend of aesthetic innovation and performance optimization. Modern designs will continue to evolve, offering visually appealing and functional solutions for automotive enthusiasts. Material advancements will play a pivotal role in enhancing durability and efficiency, ensuring that short tube headers remain a reliable choice for high-performance vehicles. By focusing on these key trends, manufacturers can deliver top-tier products that cater to the growing demands of the market.