Short tube headers in high-performance vehicles offer enhanced gas flow and reduced backpressure due to their design but require regular cleaning and inspection to prevent buildup and debris trapping. Optimal performance is maintained through addressing external fouling, internal wear, and using upgrades like high-flow air filters, proper suspension alignment, and cold air intake systems. Regular cooling and ventilation are crucial to prevent heat damage, with inspections focusing on hoses, fan operation, and muffler tips.

Maintaining short tube headers is key to maximizing their performance and extending their lifespan. Unlike traditional systems, these compact components require specialized care due to their unique design and operating conditions. This article delves into the essential maintenance tips for short tube headers, focusing on understanding their distinct needs, implementing a rigorous cleaning and inspection routine, and optimizing cooling and ventilation systems. By following these practices, you can ensure optimal efficiency and longevity of your short tube headers.

- Understanding Short Tube Headers' Unique Needs

- Regular Cleaning and Inspection Routine

- Optimizing Cooling and Ventilation Systems

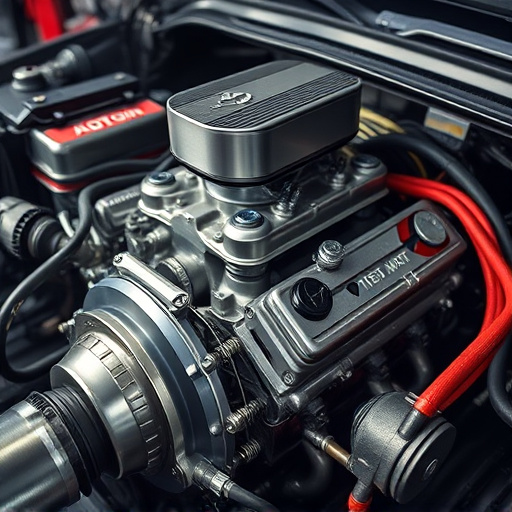

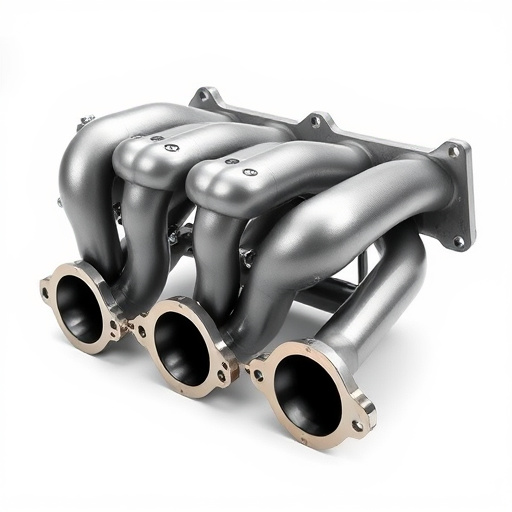

Understanding Short Tube Headers' Unique Needs

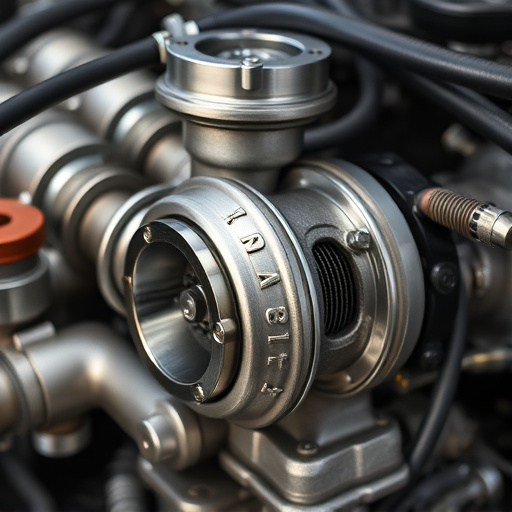

Short tube headers are a key component in many high-performance vehicles, particularly those with modified engines. Unlike traditional long tube headers, their compact design offers several advantages, such as reduced backpressure and improved gas flow, contributing to enhanced engine performance. However, this efficient layout also presents unique maintenance challenges.

Regular cleaning and inspection of short tube headers are crucial due to their high-flow characteristics. The increased velocity of exhaust gases can lead to the accumulation of deposits, affecting efficiency. Additionally, these headers often incorporate intricate design elements, such as multiple tubes and bends, which can trap debris and require meticulous attention. Maintaining optimal performance involves addressing not only external fouling but also internal wear, especially near seals and gaskets. Upgrading to high-flow performance air filters and ensuring proper alignment of suspension components can further support the longevity of short tube headers. Furthermore, considering a cold air intake system tailored for your header setup can enhance airflow, promoting consistent and efficient performance.

Regular Cleaning and Inspection Routine

Implementing a regular cleaning and inspection routine is paramount for maintaining optimal performance of short tube headers. These components, often found in high-performance vehicles equipped with cold air intakes or performance exhaust systems, are susceptible to dirt, debris, and carbon buildup over time. Establishing a consistent schedule for thorough cleaning can prevent these issues from escalating and ensure smooth operation. During inspections, visually examine the headers for any signs of damage, corrosion, or leaks. Addressing potential problems early on prevents more serious complications that could lead to costly repairs.

Regular maintenance also involves checking gaskets and seals for wear and tear, as well as ensuring proper alignment and attachment of all components. By dedicating time for this routine care, you can significantly extend the lifespan of your short tube headers, enhancing overall engine performance and efficiency.

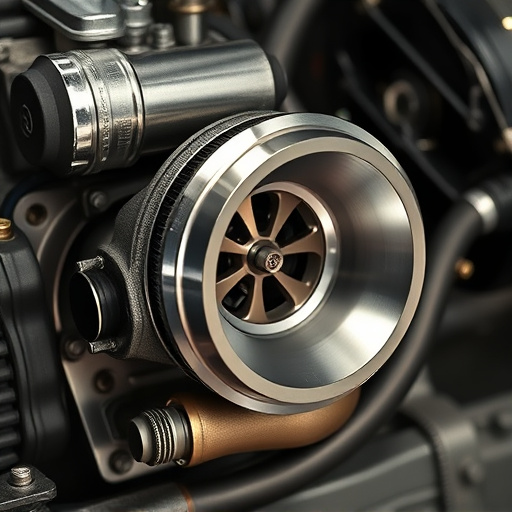

Optimizing Cooling and Ventilation Systems

Proper cooling and ventilation are essential for maintaining the longevity of short tube headers, especially in high-performance vehicles equipped with powerful engines. Optimizing these systems ensures that the headers stay cool, preventing premature aging or damage caused by excessive heat. Adequate airflow helps to dissipate heat efficiently, reducing the risk of warping or deforming the metal components over time. This is particularly crucial when upgrading to high-performance parts, as they often demand more from the cooling system.

Regular inspection and maintenance of the cooling and ventilation systems are key. Checking for any leaks in the radiator hoses, ensuring the fan operates smoothly, and examining the condition of the muffler tips can help identify potential issues early on. By maintaining these aspects, you contribute to optimal vehicle performance while preserving the integrity of your short tube headers, ultimately extending their service life.

Extending the lifespan of your short tube headers involves a combination of understanding their unique requirements, implementing regular cleaning and inspection routines, and optimizing cooling and ventilation systems. By adhering to these maintenance tips, you can ensure peak performance and longevity for your short tube headers, ultimately enhancing overall system efficiency.